On behalf of an International Client, we – network of experts – wrote pre-feasibility document for a new cement production line in Africa. The team included a GeoMining expert (Géo-CSP), an equipment and technical plans expert, a Civil Engineering expert / Project manager and myself. I was particularly in charge of “process” and “electrical distribution” part, as well as the professional formatting of the final document.

The project is being discussed with local authorities, to get all the necessary authorizations to carry out the project.

Technically, the Client wishes to use Chinese engineering companies. My experience in this field will therefore be an undisputed advantage.

For industrial development strategy reasons, and at Client’s request, no additional details can be provided concerning this project at this stage.

A second project with similar characteristics is about to emerge.

Zamba is a cement plant with a clinker capacity of around 3200tCk/d, fairly well designed, despite some weaknesses. The factory is located about a 4-hour drive west of Kinshasa.

Discussions with plant management began in early 2021, focusing on technical assistance related to improving product quality (better control of raw materials and clinker, and consequently of cement).

After various technical exchanges with the factory technical team by email, a 2-week on-site mission was organized. It highlighted:

Cooperation keeps on in the form of remote working. Depending on the needs, other missions could be organized.

The Sokhna plant is located approximately 1 hour 15 minutes from Cairo, in a desert area of Egypt. Its 4 operational lines of 5000 tCk / d each, make it an imposing site.

At the request of the Industrial Director, and following a reorganization of the plant, I was asked to build an action plan aimed at improving control room operations, the level of knowledge of operators, SOPs (Standard Operating Procedures), training… This was the subject of a first one-week mission at the end of May 2021. Better industrial performance of the plant is expected from this approach.

The following missions aim to enrich and deploy this action plan. The project is still in progress.

Everybody knows that, in the cement industry, “good raw mix makes good plant”: if raw mix is poorly mastered, the consequences, both in terms of quality and in terms of operations, are disastrous.

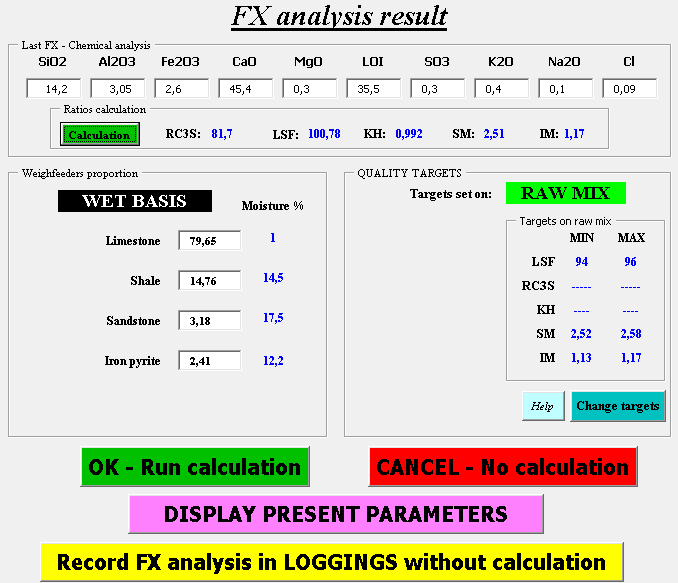

To help factories without powerful on-line raw mix control calculation tools for raw material control, I have developed a tool that is easy to set up and with the essential functionalities needed.

I am constantly enriching it so that it can become even more efficient, flexible, and easy to use.

Thus, as part of a cement plant raw logic study to eradicate its weaknesses, I can install the software (on a Windows 10 PC) and optimize the implementation of the improvement plan.

One plant in Africa and another one in Asia has used an earlier version of the soft before investing heavily in far more sophisticated tools.

Presently, two plants (Africa, Asia) have expressed their will to test the updated soft.

Discussions are on-going with: